Process Weighing

Contact usVessel Weighing & Batching

✔ Horizontal and vertical tank/reactor/hopper/blender weighing.

✔ Capacity up to 400 tons.

✔ Gain-in-weight/loss-in-weight/flow measurement and control.

✔ Model suitable foe safe and hazardous area installations.

✔ Range of modular instrumentation systems to meet process control requirements.

✔ Various operator interface options.

✔ Extensive communication support:Serial, analog, Ethernet, Modbus, Profibus.

✔ Range of load cells and mounting assemblies to meet tank profile.

PLC based Weighing & Batching System

✔ Weighing & batching solution for complete width="193" height="246"process automation.

✔ Weighing & batching of major ingredients, minor additives & manual additions.

✔ Independent & ratio metric flow rate control, heating & cooling profile control, agitation control.

✔ Automation through reputed make PLC & HMI for complete process overviewing and control. SCADA for remote control & report generation with time trend.

✔ Perfect solution for base material manufactures in paints, emulsions, adhesives & chemicals etc.

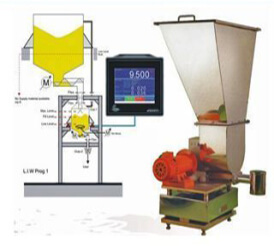

Loss in weighing Dosing

✔ Loss-in-weight system for dosing in line additives & master/slave premix.

✔ Up to 1,600 samples/second.

✔ 5.7" ultra clear touch screen.

✔ Inbuilt PID controller for adjusting flow.

✔ Reading of flow in kg/hr, tons/hr, gm/min or gm/sec.

✔ Automatic refilling without disturbing LIW process.

✔ Compatible with several communication protocols.

Belt/Conveyor Weighing

✔ Suitable for monitoring the flow of material passing on the belt or for dosage.

✔ Display of hourly flow of the material passing on belt with totalizer function.

✔ Adjustment of hourly flow of material through a PID algorithm.

✔ Facility for dosing/filling by weight or time.

✔ Integration to PLC through Modbus RTU or Profibus.

✔ Weighing Beams Suitable for dynamic online weighing.

✔ PAir of load bars with a choice of digital weight indicator.

✔ Easy installation below existing conveyor belt.

✔ Capacity up to 30 tons/hr. From 400 mm to 1200 mm width.

Checkweigher

✔ Economical & best performance model.

✔ 5.7" High resolution colour TFT touch panel.

✔ Simple & sturdy design (GMP,HACCP compliance).

✔ Dedicated controller for checkweigher i.e 1,600 samples/sec.

✔ Simple programming & 3 level password for security.

✔ Serial, Ethernet for feedback.

✔ IP30 protection. Compact checkweigher.

✔ Product speed - 90 products/min.

✔ 20 product library.

✔ Special software algorithm to minimize double product issue.

Laddle Weighing System for Steel Industry

✔ 50 years of expertise in the Steel application area.

✔ Custom designed and special load cells built for steel application. Capacities up to 40 MN.

✔ High accuracy, multi channel (up to 8) electronic indicator/controller.

✔ 20,000 samples/sec bandwidth provides very fast response.

✔ Roll force measurement systems: Increases roll life, prevents mill overloads, improves product quality.

✔ Billet length optimization system: Allows cutting of billets by weight, saves on scrap.

✔ Strip Tension Tensiometer (hot/cold/galvanizing).

✔ Laddle furnace weighing and tundish weighing.

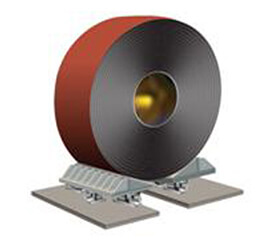

Reel Optimizing System for Paper Industry

Reel Optimizing Systems:

✔ Improves the reel quality and reduces the waste of paper caused by steel changes.

✔ Upto 4% savings in paper wastage. Eliminates bottom breaks, surface breaks and reduce turn-up breaks.

✔ Gentle control forces protect the machinery.

Disc Gap Control System:

✔ Keeps the disk gap contant in disc refiners even at considerable force variations.

Rider Roll System:

✔ Continuously sets the most efficient line pressure between the carrier rolls and the paper reel.

Coil Weighing System For Steel Industry

✔ Standalone, rugged, robust and reliable inline coli weighing system.

✔ System works on moving laod point concept - capable to withstand dynamic forces, high lateral forces, shear stress & bending effect.

✔ Capacity - upto 35 tons.

✔ Weighing system can be installed in the existing production line.

✔ Weighed data can be fed to data management software to generate production report and automatic label printing.

✔ Existing automated movement of the coli carrying trolley can be modified to include inline weighing operation thus reducing human involvement and increasing throughput.